Why Normal Maintenance of Heat Transfer Fluid is Crucial for System Longevity

Why Normal Maintenance of Heat Transfer Fluid is Crucial for System Longevity

Blog Article

Just How Heat Transfer Fluid Adds To Lasting and Economical Operations

In the modern-day commercial landscape, the role of heat transfer fluids (HTFs) in advertising sustainable and affordable procedures can not be overstated. These fluids are pivotal in maximizing thermal administration systems, thus dramatically improving power performance and reducing functional expenses. Moreover, the environmental advantages of sophisticated HTFs, with their high thermal security and low toxicity, are undeniable. They not just expand system longevity yet also add to the reduction of hazardous emissions. Yet, truth capacity of HTFs is recognized through the precise choice process, ensuring compatibility and security. However what factors should direct this crucial option?

Comprehending Warm Transfer Fluids

In the world of thermal management, heat transfer liquids (HTFs) offer as important agents for moving thermal power from one area to another. These liquids play an essential role in numerous industrial applications, including chemical processing, power generation, and a/c systems. HTFs are specifically engineered to operate within a large range of temperature levels, effectively facilitating the transfer of warmth while maintaining a steady thermal account. Their capability to operate under severe conditions-- whether heats or cryogenic levels-- makes them essential in atmospheres demanding accurate thermal control.

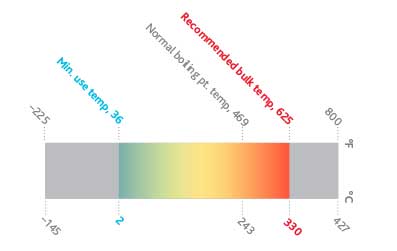

The make-up of heat transfer fluids can vary dramatically, consisting of alternatives such as mineral oils, synthetic oils, glycols, and molten salts. Each type offers distinctive advantages, such as enhanced thermal stability, low thickness, and high boiling points, which are selected based upon details functional demands. In addition, the option of HTF influences not just the efficiency of heat transfer yet likewise the durability and security of the system in which it is utilized.

As markets continue to introduce, the advancement of advanced HTFs, defined by their enhanced thermal conductivity and reduced ecological influence, is crucial for fulfilling the demands of modern-day thermal monitoring difficulties.

Enhancing Energy Efficiency

Improving power efficiency has become a paramount problem throughout numerous markets, prompting a better examination of warmth transfer fluids' duty in enhancing thermal administration systems. These fluids are essential to keeping the preferred temperature in processes, therefore decreasing power waste and boosting total system efficiency. By selecting an appropriate warmth transfer liquid, markets can dramatically boost their energy efficiency, bring about minimized power intake.

Advanced formulas of heat transfer liquids have actually been developed to endure severe temperature levels while maintaining security and performance. Boosting energy efficiency via ideal heat transfer fluid selection is not just a technical requirement but likewise an environmental critical.

Minimizing Operational Costs

Operational prices are a significant consideration for sectors looking for to keep competitive advantage, and the choice of warm transfer liquid plays an essential duty in cost administration. Picking a proper warmth transfer fluid can result in significant price financial savings by boosting system efficiency and decreasing power intake. High-performance liquids minimize thermal degradation, which subsequently lowers the frequency of fluid replacement and downtime associated with upkeep, thereby lowering operational expenses.

Additionally, heat transfer liquids with superior thermal stability and deterioration resistance extend the life-span of tools. This lowers the requirement for regular repair services and substitutes, which can be costly and disruptive to operations. By buying premium liquids, markets can achieve best site long-term reductions in maintenance costs and boost the reliability of their systems.

Furthermore, progressed warm transfer liquids commonly exhibit lower viscosity at operating temperatures, which boosts pump performance and decreases power use in fluid flow. Lots of contemporary warm transfer fluids are engineered to run efficiently over a broad temperature level array, decreasing the demand for several fluid kinds, thus streamlining stock requirements and reducing linked costs.

Ecological Influence Decrease

The press towards decreasing ecological impact has obtained energy in markets leveraging heat transfer fluids. Warmth transfer liquids (HTFs) play a critical duty in this transition, offering opportunities to enhance power efficiency and lower emissions - heat transfer fluid.

Furthermore, the use of innovative warm transfer liquids adds to improved system performance, reducing the general power consumption. This decrease not just causes expense financial savings yet additionally decreases co2 exhausts, helping in the battle versus climate adjustment. Liquids that are biodegradable and recyclable better site enhance sustainability efforts, as they decrease waste and promote round economy practices.

In addition, including HTFs into closed-loop systems prevents fluid loss and contamination of the surrounding environment. This method makes certain that fluids are reused, reducing the need for new resources and limiting waste generation. By accepting these ecologically mindful approaches, sectors can significantly lessen their eco-friendly impact while maintaining high operational effectiveness, lining up with international sustainability goals and regulative needs.

Choosing the Right HTF

Choosing the ideal warm transfer fluid (HTF) is a vital action in progressing ecological sustainability within commercial procedures - heat transfer fluid. A perfect HTF should possess a high thermal ability, low thickness, and high thermal conductivity to make sure reliable heat transfer.

When selecting an HTF, it is vital to consider its compatibility with system products to stay clear of rust and chemical reactions. This makes sure longevity and reduces maintenance prices. The fluid should be safe and eco-friendly, reducing its eco-friendly impact and making sure compliance with ecological regulations. The lifecycle cost of the HTF, including procurement, operation, and disposal, should additionally be evaluated to make certain financial feasibility.

Final Thought

Report this page